Best cnc plasma cutting machine metal plasma cutter with affordable prices

Product Features *KCP-A- 3000 model plasma and oxyfuel cutting machine, one - time finished by large gantry milling machine, increasing the surface high smoothness, rail groove is also one - time finished by large milling machine, increasing the beam rail straightness and parallelism to ensure the positioning accuracy. *Adopt hollow design, increasing structural strength, to remove the hard power and take away the heat when cutting and prevent the frame from deformation. *The Longitudinal Transmission: bilateral driving to make sure stable running *The Bilateral rack and pinion transmission without engagement gap, make the machine running smoothly when the ground deformed *Lifting Body: this configuration with a low failure rate, easy to detect. Can realize the user’s own adjustment if the mobile body tilts after a long time application. *Transmission sublance, its main torch is driven by a traction rope sublance drive, sing rop drive, flexible, no easy to break.

Top-Rated CNC Plasma Cutting Machines for Metal Fabrication high precision automated plasma cutter

Product Features --KCP-B Model is heavy,large gantry machine, the overall is eliminate stress,with high strengh,rigidity,durability,and high stability features.It can be configured with a variety of advanced cutting equipment and plasma torch,straight or oxyfuel cutting torch (special oxyfuel cutting torch for thickness 300mm).It can be equipped with making device any combination as the user's demands. --Horizontal rail adopt linear rail,longitudinal rail can be fine grinded 24kg grade or 38kg,43kg grade,to ensure high precision and durable and smooth operation of the machine. --Driving system adopt Japanese Panasonic servo motors and drivers,to ensure wide speed variable and accleration time shortly. --Lifting body adopt aluminium alloy structure,through lift-oriented and high-speed precision ball screw. --CNC Controller system adopts the highest grade industrial computer system F2500 CNC system,with large screen 15" display and excellent stability and strong anti-jamming.

Straight Metal Gantry Cutting Machine

Product Features Straight Cnc Cutting Machine Flame Gantry Straight Metal Cutting Machine Application --Applied Material: Carbon steel strip cutting. --Type: steel plate and metal sheet Mode: Cut off, hole drilling, slotting.. --Industry: Especially for steel structure construction, shipbuilding, and other metal processing industries.

Plate and Tube Integrated Cnc Plasma Cutting Machine

Product Features --Cutting steel type: round tube --Figures can be cut: variety of graphics by outspreading intersecting line, can be with bevel. --Control Axies: 3 axies. --Diameter: 60 - 600mm or customized (bigger diameter) --Bevel cutting range: oxyfuel 45 degree, plasma 45 degree. --Cutting methods: plasma and oxyfuel cutting. --Pipe max length: 12m --Pipe clamping method: chunk --Power - driven: high precision AC servo and dedicated planetary reducer --Control system: a dedicated intersection line, 6 - axis controller, with quantitative intersection line cutting macro library.

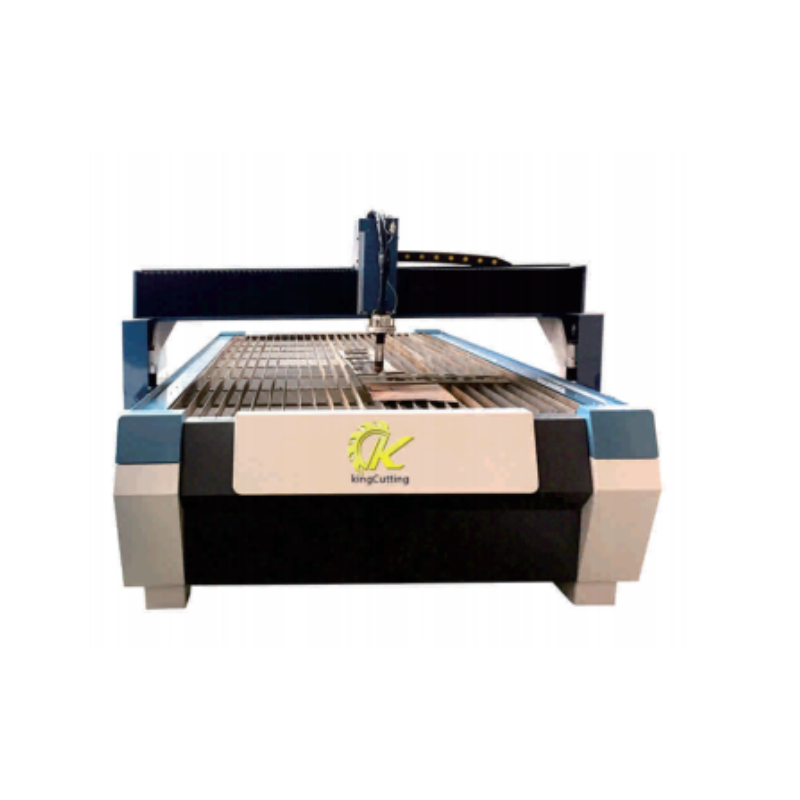

Table Plasma Cnc Cutting Machine

Specification: --Bench model, plasma, flame, both plasma and flame cutting machine --Bench structure, Y axis uses dual-motor dual-driven system, X, Y, Z axes all use dual straight rail that make the machine driving smoothly with high precision. --The kerf is small, tidy and avoid a second dressing processing. --It can apply to iron sheet, the aluminum sheet, the galvanized sheet, hardened steel plates, and metal plates and so on. --The numerical control system disposes high, the automatic striking arc, the performance is stable. --Support Wentai, Australia Fastcam, Germany IBE Software, FreeCAM software, produce standard G code format documents, also can change software to read AUTO CAD software produce DXF format documents. The control system uses the U disk to exchange processing document, easy to operate.

Plate and Tube Integrated Cnc Plasma Cutting Machine

Product Features --Cutting steel type: round tube --Figures can be cut: variety of graphics by outspreading intersecting line, can be with bevel. --Control Axies: 3 axies. --Diameter: 60 - 600mm or customized (bigger diameter) --Bevel cutting range: oxyfuel 45 degree, plasma 45 degree. --Cutting methods: plasma and oxyfuel cutting. --Pipe max length: 12m --Pipe clamping method: chunk --Power - driven: high precision AC servo and dedicated planetary reducer --Control system: a dedicated intersection line, 6 - axis controller, with quantitative intersection line cutting macro library.

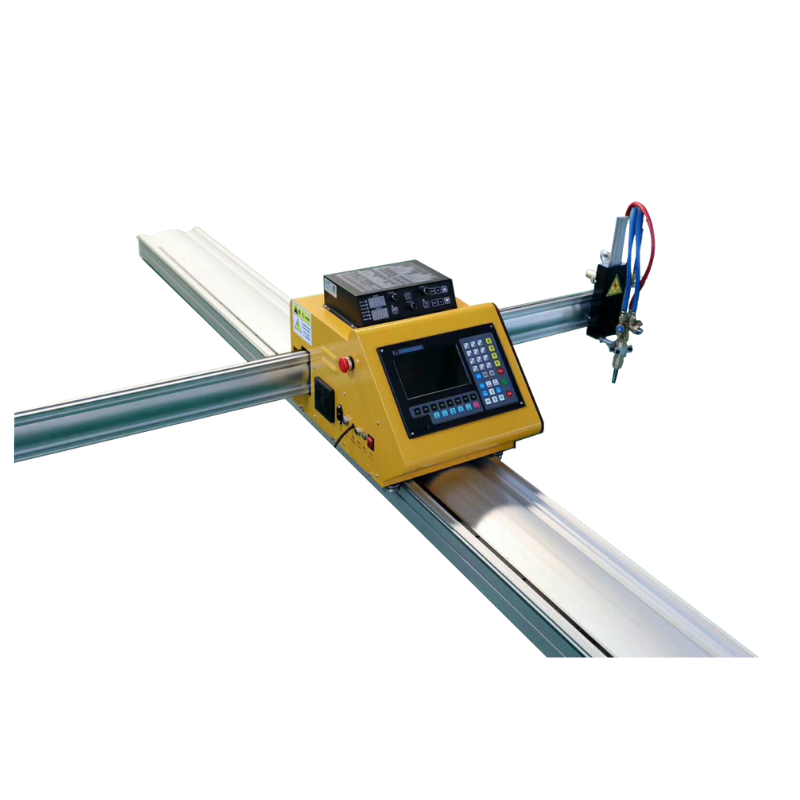

Portable Cnc Cutting Machine

Main Features: --Cross beam driving model, enables a more stable balance movement, avoid the head declining due to gravity; --Reasonable cutting area: effective 1500mm3000mm, suitable most common sheet 4ft8ft; --Light and smart, no fixed place occupation, sustain cutting on sheet directly; --Simple structure, easy for packing, delivery, installation and disassemble; --Overall processing alloy base, assure light and precise, no base shape deformation; --Cross beam and rail both with linear guide, high accuracy good stability moving --With motor enable/disable button, ensure operator and machine safety and start position random select,save material save time.

Portable Gantry Cutting Machine

Brief introduction: --Industrial Metal tube beveling machine intersection cnc 5 axis plasma automatic pipe cutting machine --CNC automatic pipe profile cutting machine is special CNC equipment which is used for cutting metal pipe automatically. --It can realize auto program and auto CNC nesting work for any complicated joint type of intertube, pipe, etc. and can cut any shapes at one time. --This product is widely used for steel structure, shipbuilding, bridge and heavy machine industries. -----Suitable for cutting cylinder branch, two or three - layer saddle cutting of the main pipe. --It is suitable for large quantities of professional intersection pipe cutting. --Cutting material: low carbon steel, stainless steel and non - ferrous metal, etc. machine can be designed according to the different needs of users.

CNC Intersection Pipe Cutting Machine

Brief introduction: --Industrial Metal tube beveling machine intersection cnc 5 axis plasma automatic pipe cutting machine --CNC automatic pipe profile cutting machine is special CNC equipment which is used for cutting metal pipe automatically. --It can realize auto program and auto CNC nesting work for any complicated joint type of intertube, pipe, etc. and can cut any shapes at one time. --This product is widely used for steel structure, shipbuilding, bridge and heavy machine industries. -------Suitable for cutting cylinder branch, two or three - layer saddle cutting of the main pipe. --It is suitable for large quantities of professional intersection pipe cutting. --Cutting material: low carbon steel, stainless steel and non - ferrous metal, etc. machine can be designed according to the different needs of users.

Efficiency & Applications H beam plasma cutting machine with high precision

Application: metal square/rectangular/round pipes and H/I/L/U beams cutting with different shapes Cutting thickness: 1 - 50mm for plasma cutting Diameter/width of workpiece: 60 - 300mm for KCP - H - 300; 60 - 400mm for KCP - H - 400, or to be customized Length of workpiece: 6000mm or to be customized Main features: --Multiple axes cutting, with profile end bevel cutting available for seamless welding. --Not only plasma torch but also flame torch can be equipped, with the cutting thickness up to 200mm, for detail cutting thickness for each cutting mode, please refer to the "Cutting mode and cutting thickness" TABLE below. --Automatic ignition when cutting by flame; --Choose different patterns directly from drawing library to meet your cutting requirements, or import AUTO CAD patterns from a USD disk to the machine, the machine will automatically cut the patterns. --A wide range of materials can be processed, including square/rectangular/round pipes and H/I/L/U beams. --All the cutting parameters can be customized to cut longer or bigger workpieces.

Reliable & efficient industrial fiber laser cutter for metal

--Fiber laser control system can be different brands, Cypcut or Weihong. --Fiber laser generator could be Max, Raycus or IPG Brands. --High-rigidity heavy chassis, reducing the vibration generated during high-speed cutting greatly. --Table double-drive structure, with imported Taiwan rack&pinion transmission system, improves the production efficiency. --High-performance cast aluminum guide rail, after finite element analysis, realizes highly accelerated speed circular arc cutting. --Open worktable, simple operation and small space occupation. --Auto-restart after power blackout and continue previous process. --3-in-1 control system makes processing more stable. --High accuracy industrial camera provides high positioning precision. --High efficiency water-cooling spindle motor configuration. --Independent control cabinet, separated strong power and weak power design, easy to maintain.

Gantry Fiber Laser Cutting Machine

--Fiber laser control system can be different brands, Cypcut or Weihong. --Fiber laser generator could be Max, Raycus or IPG Brands. --Customized format ranging from 3 to 8 meters, tailored to the workshop space; --Gantry dual drive ensures high-stability and high-precision cutting; --The cutting head moves laterally, making the cutting of wide plates more powerful; --Open worktable, simple operation and small space occupation; --Auto restart after power blackout and continue previous process. --3-in-1 control system makes processing more stable. --High accuracy industrial camera provides high positioning precision. --High efficiency water-cooling spindle motor configuration. --Independent control cabinet, separated strong power and weak power design, easy to maintain.

Plate and Tube Integrated Laser Cutting Machine

cnc laser cutting machine 3000w fiber laser cutting machine laser pipe cutting machine suitable for stainless steel,carbon steel,silicon steel,aluminum alloy,titanium alloy,galvanized steel,pickle plate,aluminum - plating zinc plate,metallic copper and other metals. 1.Fiber laser cutting machine adopts 3D generation aluminum gantry. It is manufactured with aerospace standards and formed by 4300 tons press extrusion molding.After aging treatment,its strength can reach 6061 T6 which is the strongest strength of all gantries.Aviation aluminum has many advantages,such as good toughness,light weight,corrosion resistance,anti - oxidation,low density,and greatly increase the processing speed. 2.Without manual operation,it can focus automatically:Without manual focusing.Bigger adjustment range.Long service life 3.Independent Control Cabinet:Dust - proof:All electrical components and laser source are built - in to the independent control cabinet with a dust - proof design to prolong the lifespan of the electrical components.Automatic Thermostat:The control cabinet is equipped with air conditioner for automatic constant temperature.This can prevent excessive temperature damage to components in summer. 4.Stainless Steel Protection Design: The operating area adopts a 304 stainless steel design to prevent high temperature cutting sparks from damaging the machine’s surface.

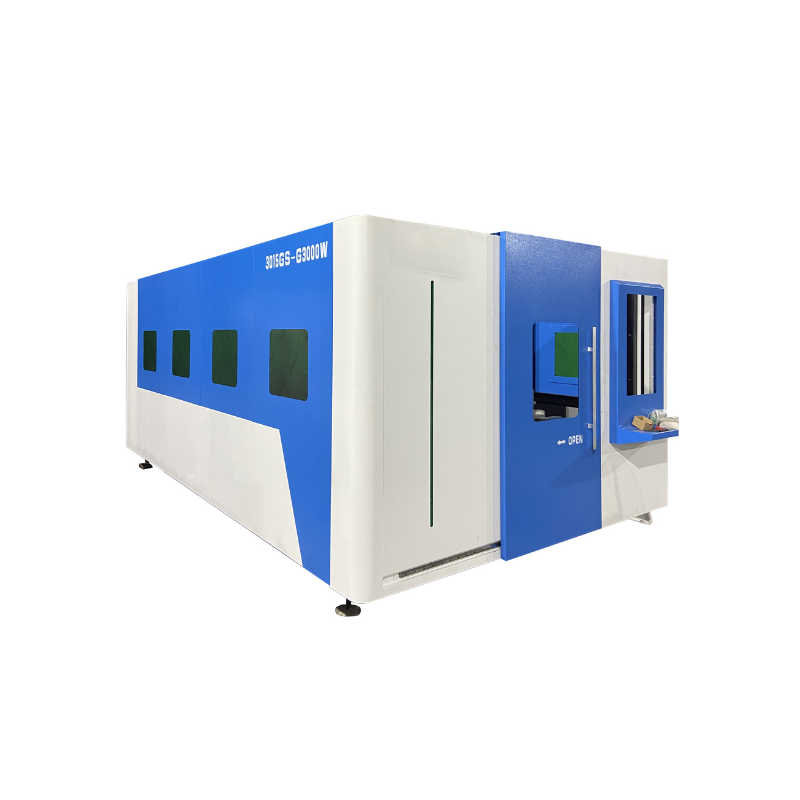

Full Covered Fiber Laser Cutting Machine

--Full covered fiber laser cutting machine can carry up to 6000W/12000w/20000w/30000w laser power, so cutting some thick plate, it is a very good choice. For example, agricultural machinery, textile machinery, food machinery, power construction machinery and other large machinery and equipment manufacturing, usually use high power fiber laser cutting machine for processing. --Suitable for stainless steel, carbon steel, silicon steel, aluminum alloy, titanium alloy, galvanized steel, aluminum - plating zinc plate, copper, and other metals. --Safety and No Pollution with a fully enclosed design. --The observation window adopts an European CE standard laser protective glass. --The smoke produced by cutting can be filtrated inside, it's non - polluting and environmentally friendly.

Handheld laser welding machine

Product Features: 1. Ergonomic design, easy to move, compact structure, easy to operate and maintain. 2. Lightweight and flexible handheld welding head, can be welded at any angle, integrated with gas protection system and automatic feeding device. Protection system and automatic feeder. 3. Small volume, only 0.23 cubic meters, easy to load into the car. 4. Strong welding, fast welding speed, smooth weld; 5. Fast welding speed, efficency is 3 - 10 times that of argon arc welding.

Automated Plasma Cutting Machine cnc steel plasma cutter professional factory

Product Features *KCP-A- 3000 model plasma and oxyfuel cutting machine, one - time finished by large gantry milling machine, increasing the surface high smoothness, rail groove is also one - time finished by large milling machine, increasing the beam rail straightness and parallelism to ensure the positioning accuracy. *Adopt hollow design, increasing structural strength, to remove the hard power and take away the heat when cutting and prevent the frame from deformation. *The Longitudinal Transmission: bilateral driving to make sure stable running *The Bilateral rack and pinion transmission without engagement gap, make the machine running smoothly when the ground deformed *Lifting Body: this configuration with a low failure rate, easy to detect. Can realize the user’s own adjustment if the mobile body tilts after a long time application. *Transmission sublance, its main torch is driven by a traction rope sublance drive, sing rop drive, flexible, no easy to break.

CNC Plasma Cutting Systems Buy Reliable Metal Cutting Machines

Product Features *KCP-A- 3000 model plasma and oxyfuel cutting machine, one - time finished by large gantry milling machine, increasing the surface high smoothness, rail groove is also one - time finished by large milling machine, increasing the beam rail straightness and parallelism to ensure the positioning accuracy. *Adopt hollow design, increasing structural strength, to remove the hard power and take away the heat when cutting and prevent the frame from deformation. *The Longitudinal Transmission: bilateral driving to make sure stable running *The Bilateral rack and pinion transmission without engagement gap, make the machine running smoothly when the ground deformed *Lifting Body: this configuration with a low failure rate, easy to detect. Can realize the user’s own adjustment if the mobile body tilts after a long time application. *Transmission sublance, its main torch is driven by a traction rope sublance drive, sing rop drive, flexible, no easy to break.

Industrial cnc plamsa cutters metal fabrication heavy-duty plasma machine

Product Features *KCP-A- 3000 model plasma and oxyfuel cutting machine, one - time finished by large gantry milling machine, increasing the surface high smoothness, rail groove is also one - time finished by large milling machine, increasing the beam rail straightness and parallelism to ensure the positioning accuracy. *Adopt hollow design, increasing structural strength, to remove the hard power and take away the heat when cutting and prevent the frame from deformation. *The Longitudinal Transmission: bilateral driving to make sure stable running *The Bilateral rack and pinion transmission without engagement gap, make the machine running smoothly when the ground deformed *Lifting Body: this configuration with a low failure rate, easy to detect. Can realize the user’s own adjustment if the mobile body tilts after a long time application. *Transmission sublance, its main torch is driven by a traction rope sublance drive, sing rop drive, flexible, no easy to break.